Recyclable and Compostable packaging and components manufacturer

Nissha's ecosense molding provides sustainable packaging made of pulp and biocomposite as eco-friendly alternatives to traditional plastic solutions – Sulapac®, Pulp-Injection, PaperFoam® From product design to full production service in Europe.

Nissha's ecosense molding is our product brand to offer an eco-friendly alternative to plastic products.

Pulp-Injection and PaperFoam® are paper recyclable solutions primarily made from pulp, while Sulapac® is composed of bio-based polymer and various biomass materials such as wood chip and natural mineral clay to achieve unique textures and superior functionality. All are made of bio-based material.

Nissha offers customized solutions to meet our customers' needs, from design to mass production, on a global scale.

-

Sulapac® Jars and closures for dry foods, supplements and cosmetics

Sulapac®Learn more -

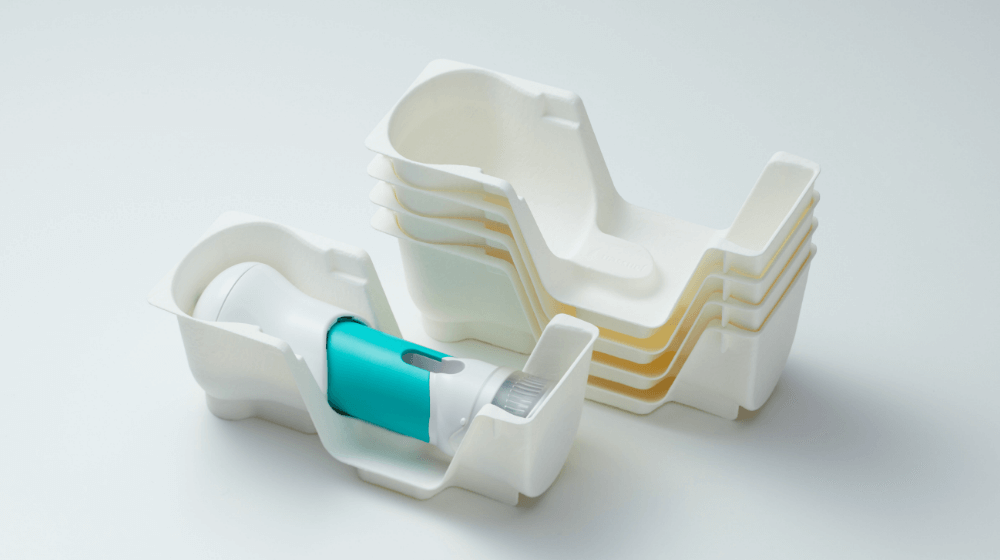

Pulp-Injection Primary/Secondary packaging and components for devices

Pulp-Injection Learn more -

PaperFoam® Secondary packaging for consumer goods, electrical devices and pharmaceutical devices

PaperFoam® Learn more

Awards and achievements

-

Packaging Innovation Awards Winner

at Pharmapack Europe 2024 -

Innovation gallery in PCD in Paris 2024

-

Zukunftspreis 2023 awarded by IHK Erfurt

(Innovations Awards) -

Innovation award in Cosmetic Business 2023